We tailor your needs from idea to precision tool for plastic profile production.

HERE, THE TOOL DEFINING THE FINAL PRODUCT WILL BE CONSTRUCTED

Primo’s in-house tooling centre is your guarantee for the best possible tooling solution and a smooth time-to-market process.

OPTIMISE THE PRODUCTION

Tool development takes place in close collaboration with the customer to optimise the production tools according to the customer's needs.

Continuous quality control during test and serial production ensures an efficient manufacturing process with consistent, quality plastic products as the end result.

The best tool manufacturers

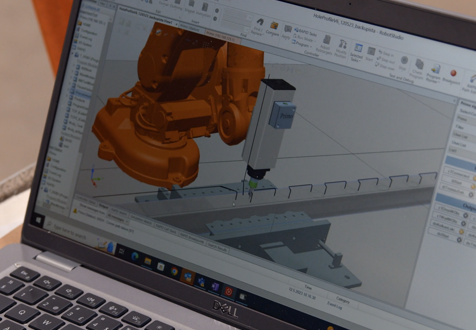

We use CAD/CAM systems and have an extensive capacity in terms of CNC-controlled milling and finishing centres, manned by thoroughly-trained teams of highly-qualified designers and toolmakers.

THE EXTRUSION PROCESS

The various types of plastics all have different structures that determine their properties, like rigid or soft, flexible, and so on. These characteristics, and their combinations, are limited only by the imagination.

Reshaping products and igniting innovation in polymer extrusion.

Engaged customers, from designers to engineers, fuel meaningful discussions. Our shared material language combines their needs with our expertise, refining plastic profiles for optimum results.

Decades of cross-industry polymer expertise, makes Primo your dedicated partner providing specialized units for medical tubing, subsea cables, and automotive gaskets..

Clients arrive with finished drawings or sketches, opening doors for collaborative improvement. Thanks to the right polymer, tool, and our material knowledge, we enhance profiles and their functions. With accumulated international experience, we're adept at suggesting superior polymers and faster processes.

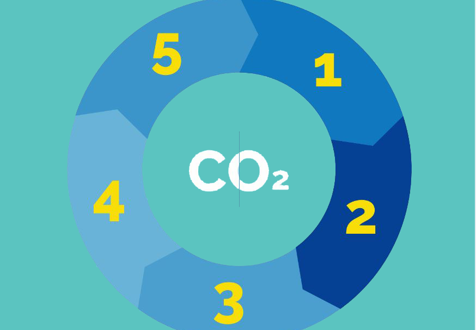

The right material is a crucial factor for the properties of your profile and final product. Plastic's adaptability creates intricate shapes, offering flexibility, strength, and diverse applications. Primo leads with superior plastic solutions, embracing sustainability and recyclability.

Versatility: Plastics serve countless roles, from insulation to decoration.

Durability: Resistant to impact, weather, and chemicals, plastics offer reliability.

Efficiency: Low friction suits moving parts, ensuring longevity.

Eco-Friendly: Energy-efficient and recyclable, plastics champion sustainability.

Elevate your products and accelerate time to market with expertise. Our comprehensive approach encompasses tooling, profile design, material expertise, and streamlined development. Harnessing these elements transforms your vision into superior products, while expediting your journey to market success.

For us, every new concept is a new challenge that involves all stakeholders. But our journey doesn't stop there. Every plastic product has the potential for improvement, expansion or material innovation.

Your customers may require additional documentation to meet evolving regulations.

We see the endpoint as an exploration of uncharted territory, a springboard for a new journey ahead.

Computer control and monitoring ensures that all information is updated during production. Our traceability system is an integrated part of our ERP system, Oracle. The quality module that guarantees total control and documentation. All Primo products are fully documented and data sheets can be supplied on request.

Interested in other parts of our process?

Our Business Areas

Insights

Our people are dedicated to finding solutions to every challenge. That spirit makes for some great stories.

View all news & articles

Do you want to know more about our plastic panels and insulation profiles?

Jaakko Salo

Group Commercial DirectorJaakko Salo is the group's head of sales, with a broad understanding of the different markets and industries. He is also our specialist in linear lighting profiles, busbars, and diffusers: As an experienced expert in the field, Jaakko's many years of experience and contributions show his deep comprehension of the possibilities of the linear lighting landscape. He's committed to innovation in his work and has collaborated with architects, designers, and industry partners to create lighting profiles that go beyond mere functionality. Jaakko can help you shape your success and light the way for the industry.